Industrial torque sensor

http://www.sensortelemetrie.de

http://www.sensortelemetrie.de

inductive. minimalist. plug & play.

Q-Torque torque transducer

In the context of the interconnected factory, the sensor technology on the machines for control and monitoring is of elementary importance. Torque plays a significant role here. Although strain gage technology has proven itself for more than 80 years for measuring torque, it has only been used for series production in special cases due to the high application costs. For the mass applications desired today, the physical approaches based on magnetic technology have not been successful in harsh industrial environments.

With the help of MANNER’s know-how in the field of non-contact signal transmission, strain gauge technology and automated production engineering, MANNER has created the product Q-Torque.

With Q-Toque MANNER offers a torque transducer for industrial applications in the sense of Industry 4.0. The system was developed for series applications with focus on attractive costs.

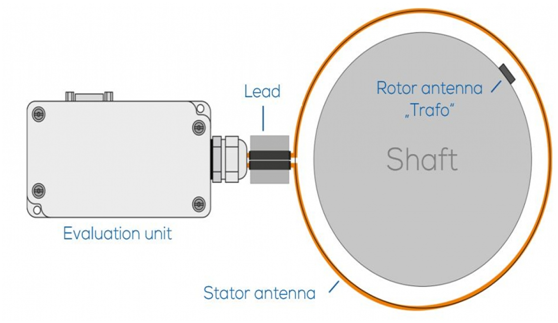

The Q-Torque kit works according to the robust and proven principle of inductive telemetry. Unlike the OptiMA systems, the stator antenna is designed as an induction loop and the rotor antenna is point-shaped and minimalist. This eliminates the need for the complex rotor ring.

The entire arrangement on the rotor consists only of the measuring amplifier with telemetry interface and the torque sensor elements. A characteristic feature is the mounting without soldering iron. The rotor components are only attached to the shaft by means of epoxy and glass fiber. It can be mounted without electronic knowledge.

The rotating part of the Q-Torque system – the measuring amplifier, the strain gauge sensors – are fed by a stationary ring-shaped induction loop.

The data is output as an analog voltage signal 0 to 10 V.

With the integrated speed measurement all data for dynamic power flow determination is available.

MANNER Q-Torque has an automatic alignment of the rotor and stator electronics to correct mounting tolerances and to ensure best results in terms of range and signal quality.

Due to the variable length of the stator induction loop for shaft diameters from 220mm to 400mm) the system is very flexible and frequent changes of series are faster to operate. The system is Plug&Play, no soldering is necessary.

Thus, the system can be put into operation without in-depth knowledge of sensor telemetry and generates flawless measurement results.

- Solid technology, predestined for use in mechanical engineering

- Can be integrated into existing integrations

- Low cost

- Real time – 3300 measurements per second

- low commissioning costs

- Maintenance-free

- bandwidth 1 kHz at 16-bit resolution